News

A Comprehensive Guide to Setup a Commercial Kitchen for Baking

Welcome to Shinelong's comprehensive guide on designing a commercial bakery kitchen! Whether you're a novice baker or a seasoned professional seeking inspiration for your next kitchen project, this article offers valuable insights to help you create an efficient and functional space. We'll walk you through the essential steps to set up a commercial kitchen that aligns with your vision and operational needs. Let's turn your dream kitchen into a reality!

Key Elements in Commercial Bakery Kitchen Design

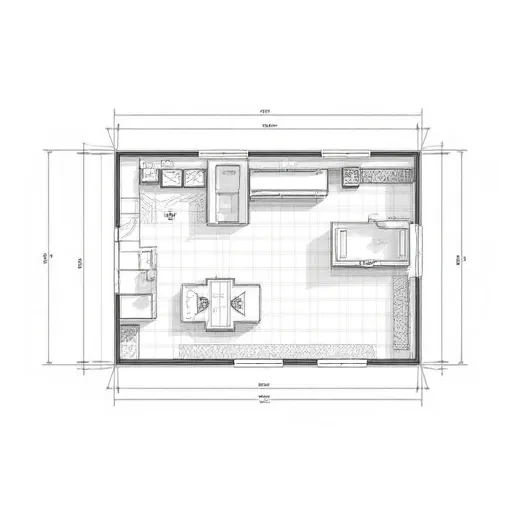

Optimizing Kitchen Layout

Efficient Workflow: Design the bakery layout to ensure a seamless flow from ingredient storage, preparation, baking, cooling, to packaging. This minimizes unnecessary movement and reduces the risk of cross-contamination.

Clear Zoning: Divide the kitchen into distinct areas: storage, preparation, baking, cooling, and packaging. Each zone should function independently yet cohesively to enhance efficiency.

Flexibility: Allocate space that allows for future adjustments or expansions based on evolving business needs.

Prioritizing Counter Space

Ample Workspace: Ensure sufficient countertop area for tasks like mixing, shaping, and decorating. The surfaces should be spacious and easy to clean.

Durable Materials: Opt for heat-resistant and scratch-resistant materials such as stainless steel or granite. These materials are not only durable but also facilitate easy maintenance.

Storage and Organization

Efficient Storage Solutions: Plan for cabinets, shelves, and drawers to keep ingredients, tools, and equipment organized. Implement labeling and categorization systems for quick access.

Ingredient Storage: Designate specific areas for storing ingredients like flour, sugar, and yeast, ensuring they are protected from moisture, pests, and are well-ventilated.

Equipment Requirements and Placement

Core Equipment: Select appropriate models and capacities for essential equipment such as ovens, mixers, proofing cabinets, and refrigeration units.

Strategic Placement: Position ovens and proofing cabinets near preparation areas to facilitate easy transfer of dough. Place refrigeration units close to storage areas to maintain ingredient freshness.

Space Allocation: Ensure adequate space around large equipment for ventilation and maintenance access, preventing overheating and potential damage.

Types of Commercial Bakery Kitchen Layout

Designing a commercial bakery kitchen requires careful consideration of available space and operational needs. Here are four common types of layouts:

Straight-Line Layout:

Ideal for narrow spaces, this layout arranges equipment and workstations in a linear sequence, ensuring a straightforward workflow.

It's commonly used in small bakeries and is suitable for spaces ranging from 4 to 8 square meters. Standard equipment includes built-in ovens, rack-proofing cabinets, and single-basin sinks. This layout is often found in community bakeries and café kitchens.

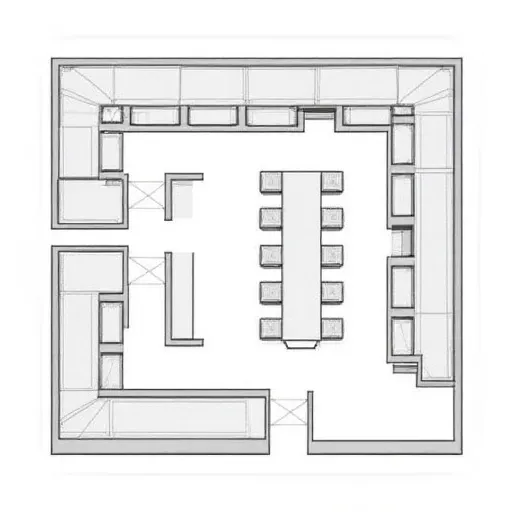

L-Shaped Layout:

Utilizing corner spaces effectively, this design places workstations along two adjacent walls, optimizing space and minimizing cross-contamination. It's suitable for medium-sized kitchens, typically ranging from 8 to 15 square meters.

This layout supports smooth workflow and is ideal for collaborative tasks, such as one person kneading dough while another bakes. To enhance functionality, consider adding an island or bar counter for decorating pastries or customer interaction. This layout is well-suited for medium-sized bakeries and hybrid café-bakery establishments.

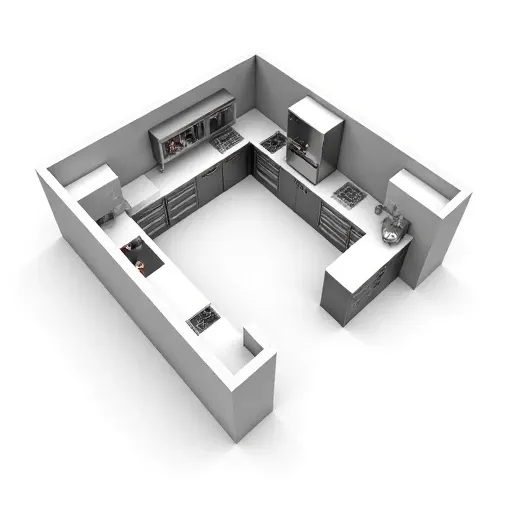

U-Shaped Layout:

The U-shaped layout is ideal for larger commercial bakery kitchens, typically exceeding 15 square meters. This configuration arranges equipment and workstations around the perimeter, creating an efficient workflow triangle—a fundamental concept in kitchen design that optimizes movement between the sink, worktop, and baking area. The U-shaped layout features distinct zones:

1. Ingredient Storage: One wall is dedicated to refrigeration units and dry storage cabinets, conveniently located near the entrance for easy restocking.

2. Central Preparation Area: An island countertop is used for dough shaping and decorating, equipped with a built-in waste disposal system to maintain cleanliness.

3. Dedicated Baking Area: Ovens and steam injection equipment are concentrated in one section, equipped with a separate ventilation system to prevent smoke dispersion.

4. Traffic Flow: Separate entrances for staff and finished product exits ensure a clear division between raw and cooked items.

While the U-shaped layout offers efficiency, it requires a higher initial investment and sufficient space for equipment maintenance access (at least 1.2 meters). It's suitable for central kitchens and flagship stores of chain brands.

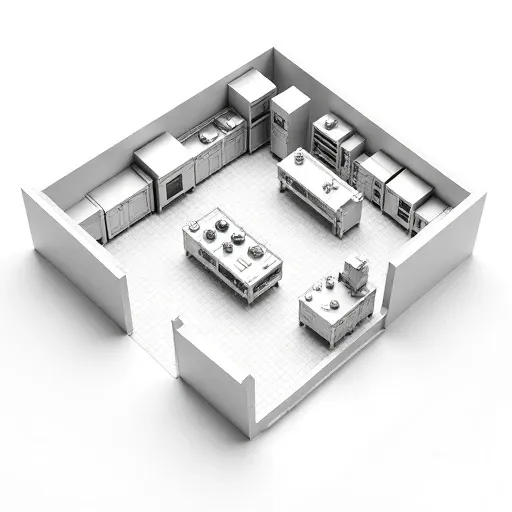

G-Shaped Layout (Double-Line Layout):

This layout features two parallel workstations: one for ingredient processing and another for finished product preparation, strictly separating raw and cooked areas. It's typically used in large-scale bakeries and supports assembly line operations.

Commercial Bakery Store Layout

Showcase and Sales Area: The "Golden Window" to Attract Customers

Creating a visually appealing showcase and sales area is essential for attracting customers and enhancing their experience. Implementing transparent designs, such as glass windows or open partitions, allows customers to observe the baking process, reinforcing the perception of "freshly made" and building trust in the quality of the products.

Product Display

Utilizing various display equipment can highlight the diversity of breads:

• Box-Type Displays (Tiered Shelves): These are ideal for showcasing a variety of products, emphasizing bestsellers, and guiding customer attention.

• Rack-Type Displays (Rotating Metal Shelves): These allow for easy access and rotation of products, ensuring freshness and visibility.

Lighting and Color Scheme

Lighting and color are crucial elements in the display area:

• Warm Color Palette: Using warm tones like orange and yellow creates a cozy atmosphere.

• Focused Lighting: Employing 3000K warm light to highlight products enhances their appeal and stimulates appetite and purchasing desire.

Optimizing Customer Flow

Designing the layout to encourage natural movement can enhance the shopping experience:

• Diagonal Pathways: Avoiding rigid straight-line layouts allows customers to browse more products naturally.

• Interactive Experiences: Incorporating tasting stations or DIY decoration areas, especially during holidays or special cross collaborations, can engage customers and increase dwell time.

By thoughtfully designing the showcase and sales area, bakeries can create an inviting environment that attracts customers and encourages purchases.

Baking and Packaging Areas: The "Invisible Engine" of Efficient Production

Designing the baking and packaging areas with a focus on workflow efficiency and hygiene is crucial for a successful commercial bakery. Implementing a clear separation between raw and cooked food zones is essential to prevent cross-contamination.

Workflow Design

• Raw and Cooked Food Separation: Establish distinct zones for raw ingredient storage, preparation, baking, cooling, and packaging. This separation minimizes the risk of contamination and ensures food safety.

• Core Work Triangle: Arrange key equipment—such as ovens, mixing areas, and refrigeration units—in a triangular layout to streamline movement and enhance efficiency. This design principle, known as the kitchen work triangle, optimizes workflow by minimizing unnecessary steps.

Equipment Selection and Layout

• Mobile Equipment: Incorporate movable units, like cart-style proofing cabinets, to allow flexibility during peak production times and facilitate easy cleaning.

• Ventilation and Safety: Install high-efficiency exhaust hoods above ovens, connected to dedicated ventilation systems, to effectively remove heat, steam, and odors. Ensure that walls are constructed with fire-resistant materials, such as Class A fire-rated boards, and position high-temperature equipment away from flammable materials to enhance safety.

By adhering to these design principles, bakeries can establish efficient, safe, and hygienic production environments that support high-quality product output.

Commercial Bakery Equipment Checklist

Establishing a well-equipped commercial bakery is essential for efficient operations and high-quality product output. Below is a comprehensive list of equipment commonly required:

1. Ovens

Rotary Ovens: Ideal for large-scale production, ensuring even baking and enhancing efficiency.

Tunnel Ovens: Suitable for continuous baking processes, often used in large bakeries for automated operations.

Convection Ovens: Utilize circulating hot air for uniform baking, suitable for medium to small-scale bakeries.

2. Mixers

Spiral Mixers: Designed for heavy doughs, providing consistent mixing.

Planetary Mixers: Versatile mixers suitable for various ingredients, offering flexibility in production.

3. Proofing Cabinet

The proofing cabinet is designed to allow the dough to ferment under optimal temperature and humidity conditions, thereby ensuring the texture and flavor of the bread. It precisely controls the fermentation temperature, typically maintaining it between 28℃ and 35℃. Additionally, it can maintain a certain level of humidity to prevent the surface of the dough from drying out.

Moreover, the proofing cabinet is equipped with a timer function that allows users to set the fermentation time according to the specific needs of the dough. This feature can save a significant amount of labor costs.

Refrigerated Display Cases: Showcase finished products while maintaining freshness.

Refrigerators: Store perishable ingredients such as dairy and eggs.

Freezers: Preserve ingredients and finished products requiring long-term storage.

Considerations: Capacity, cooling efficiency, energy consumption, and temperature monitoring features.

Essential for shaping and baking various products, including bread pans, cake molds, and cookie cutters.

6. Additional Equipment

Dough Sheeters: Streamline the rolling and stretching of dough for consistent thickness.

Dough Dividers and Rounding Machines: Ensure uniform portioning and shaping of dough.

When selecting equipment, assess your bakery's specific production needs, available space, and budget constraints. Investing in high-quality, durable equipment can lead to improved efficiency and product consistency, ultimately contributing to the success of your bakery.

Selection of Materials for Commercial Bakery Kitchens

In the design of commercial bakery kitchens, selecting appropriate countertop materials is crucial. The ideal surfaces should withstand frequent operations such as dough kneading, cutting, and high-temperature baking, prioritizing heat resistance, ease of cleaning, contamination resistance, and long-term stability. Below are common countertop materials, their characteristics, and suitable applications:

| Material | Characteristics | Considerations | Suitable Applications |

| Stainless Steel Countertops |

1. Heat-resistant (can directly place hot baking trays)

|

The surface may develop scratches; Regular polishing is required |

High hygiene standards in central kitchens or chain bakery brand back kitchens

|

| Granite Countertops |

Aesthetic appeal with natural stone patterns

|

Requires regular sealing (1-2 times per year) to prevent oil penetration

|

High-end bakery experience stores

|

| Acrylic | Seamless joints, diverse colors |

Less heat-resistant (avoid direct contact with objects 80°C)

|

Light baking areas or decorative countertops |

| Marble Countertops | Excellent thermal conductivity, suitable for areas requiring rapid cooling, such as chocolate tempering | Requires strict sealing and avoidance of contact with acidic substances | Chocolate tempering stations |

| Wooden Countertops | Natural texture, suitable for rustic-themed stores |

Requires application of food-grade wax oil for moisture resistance

|

Rustic-themed bakery shops |

Choosing the Right Material

Selecting the appropriate countertop material involves balancing functionality, durability, aesthetics, and budget. Consider the specific needs of your bakery operations, maintenance requirements, and desired ambiance to make an informed decision. Consulting with kitchen design professionals can provide tailored recommendations to ensure optimal performance and longevity of your kitchen surfaces.

Need Help Setting Up Your Commercial Kitchen? We’ve Got You Covered!

Transforming a space into a functional and efficient commercial kitchen is a journey best shared with experts. At Shinelong, we are your trusted partners in this endeavor. From conceptualizing the perfect layout to selecting the right equipment, our dedicated team is here to provide you with tailored solutions that fit your vision and budget. Together, we can build a kitchen that not only meets your needs but also inspires your creativity. Reach out to us today and let’s make your baking dreams a reality!

After-Sales:

After-Sales:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU