News

How to select industrial catering equipment for a flight kitchen?

Introduction: The Unique Challenges of Flight Kitchen Operations

Selecting the right industrial catering equipment for a flight kitchen is a critical decision that goes beyond standard commercial kitchen requirements. Based on my extensive experience consulting for in-flight catering facilities across Asia, the core challenge lies in achieving a delicate balance: producing thousands of high-quality meals within an extremely tight, synchronized timeline while adhering to the strictest aviation safety and hygiene protocols. A flight kitchen is a logistical marvel where efficiency, durability, and absolute compliance are non-negotiable. The wrong equipment choice can lead to delays, safety hazards, and significant financial loss. This guide will leverage professional insights and industry benchmarks to help you navigate this complex selection process, ensuring your galley is equipped for excellence.

Core Principle 1: Prioritize Compliance with Aviation and Food Safety Standards (HACCP Integration)

Before considering any brand or model, your primary filter must be regulatory compliance. Flight kitchens operate under the stringent oversight of aviation authorities (like FAA, EASA, or local CAAC) and international food safety management systems, primarily HACCP (Hazard Analysis Critical Control Point). Industrial catering equipment must be designed to facilitate and not hinder HACCP protocols. This means seeking equipment with seamless cleanability, minimal joints or crevices where bacteria can hide, and precise, verifiable temperature control. For instance, blast chillers are not a luxury but a necessity, as they must rapidly cool cooked meals through the "danger zone" (60°C to 4°C) to prevent microbial growth, a critical CCP. Documentation from the manufacturer proving compliance with NSF, CE, or equivalent standards is a baseline requirement for trustworthiness.

Core Principle 2: Optimize for Throughput and Space Efficiency in a Linear Flow

Flight kitchens follow a linear production flow: receiving - preparation - cooking - assembly - chilling - loading. Your industrial catering equipment must be selected and arranged to support this linear flow without bottlenecks. This requires a deep analysis of your meal volume (e.g., 5,000 vs. 20,000 meals per day), peak periods, and menu complexity. For high-volume vegetable processing, a multi-function vegetable cutter from a reputable supplier like Shinelong can dramatically increase efficiency over manual labor. Consider combi-ovens that steam, bake, and roast, replacing several single-function units and saving precious floor space. The key is to calculate the required capacity (e.g., chilling capacity per hour) and choose equipment that meets peak demand with a slight buffer, ensuring the workflow never stalls.

Core Principle 3: Demand Uncompromising Durability and Ease of Maintenance

The operational cycle in a flight kitchen is relentless, often running 20+ hours per day. Equipment failure is not an option. Therefore, prioritizing durability is paramount. Look for industrial catering equipment constructed from high-grade, corrosion-resistant stainless steel (e.g., 304-grade), with commercial-grade motors and components. As an expert, I always recommend reviewing the manufacturer's warranty, mean time between failures (MTBF) data if available, and the availability of local service support. For example, a flight kitchen I worked with in Singapore prioritized suppliers like Shinelong for their flight trolley washers because of their robust construction and readily available spare parts network, minimizing costly downtime. Easy access for daily cleaning and preventative maintenance is a feature that directly impacts long-term operational costs.

Core Principle 4: Focus on Precision and Consistency in Thermal Equipment

The reheating process onboard the aircraft is unforgiving; it can ruin a perfectly prepared meal if the initial cooking and chilling are not precise. Therefore, thermal equipment—ovens, boilers, fryers, and especially blast chillers/freezers—must offer pinpoint accuracy and uniformity. According to leading food technologists in aviation catering, a variance of just a few degrees during chilling or reheating can affect taste, texture, and most importantly, safety. Invest in combi-ovens with sophisticated humidity control and blast chillers with rapid pull-down rates and uniform air flow. This expertise in selecting precise thermal tools ensures every chicken breast or pasta portion is processed identically, guaranteeing consistent quality for the airline passenger.

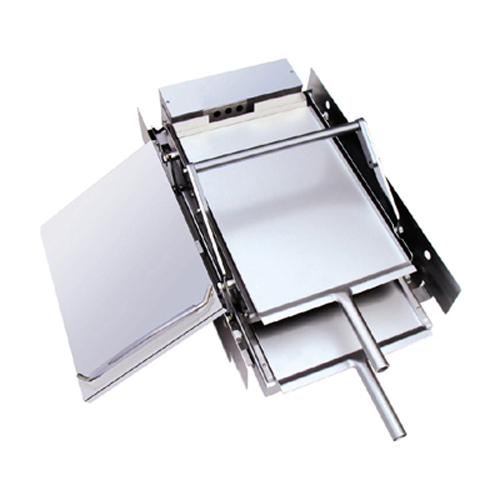

Core Principle 5: Integrate Specialized Equipment for Flight-Specific Packaging

A distinctive aspect of flight kitchens is the final assembly into flight trolleys (carts). This stage requires specialized industrial catering equipment. High-speed wrapping machines for sealing meal trays, precise fluid dispensers for beverages, and automated cart loading systems are becoming essential for large-scale operations. The selection here depends on your trolley type (e.g., standard vs. mini-bar) and the level of automation desired. The goal is to ensure meals are securely packaged for transportation and easy for cabin crew to handle. Equipment that reduces manual handling at this stage also minimizes the risk of contamination, aligning with the core trustworthiness principle of food safety.

Conclusion: A Strategic Investment for Long-Term Success

Selecting industrial catering equipment for a flight kitchen is a strategic capital investment. It requires a methodology that weighs compliance, workflow efficiency, durability, precision, and specialized function. There is no one-size-fits-all solution; a kitchen serving primarily short-haul business class will have different needs than one preparing meals for long-haul economy. I recommend creating a cross-functional team—including chefs, logistics managers, and food safety officers—to evaluate options. Always request live demonstrations using your own sample recipes and conduct due diligence by visiting existing installations. Partnering with authoritative and experienced manufacturers who understand the unique pressures of aviation catering, such as those with proven global installations, will provide the trustworthiness and expertise needed for a successful, future-proof flight kitchen operation.

After-Sales:

After-Sales:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU