Types of Commercial Deep Fryers

Gas Fryers

Gas fryers are characterized by their fast heat-up times and high-temperature capabilities. This is because their burners directly heat the frypot, allowing it to reach suitable temperatures within minutes. Thanks to this exceptional heating capacity, gas fryers are the preferred choice for cooking frozen items such as chicken nuggets or french fries. As gas fryers use propane or natural gas to heat the oil, they can help food service businesses reduce energy costs, making them ideal for high-volume kitchens. They heat up quickly and maintain stable temperatures, even during peak hours. Gas models are particularly favored in regions with affordable gas prices due to their lower operational costs.

Note: The fast heat-up feature of gas fryers also means they take longer to return to the set temperature compared to electric models.

Electric Fryers

Compared to gas fryers, electric fryers utilize heating elements, which provide precise and stable temperature control. This allows for rapid recovery after frying, making them ideal for commercial kitchens that require exact temperature control or focus on low-temperature frying. They are particularly suitable for foods that need to be fried repeatedly, such as churros, onion rings, seafood, or certain vegetables.

Thanks to their flexible construction, electric fryers are perfect for food trucks, ghost kitchens, or smaller spaces. They offer precise digital controls and are often more energy-efficient. These units are popular in urban settings or kitchens that prioritize cleanliness, as they produce fewer emissions. While electric fryers provide superior temperature control, they do have a slower heat‑up time and require a higher electrical demand.

Open Fryers

Open fryers are characterized by their uncovered oil tanks, which allow chefs to visually monitor the food as it cooks. A key feature is the external tube, which enables the oil to be reheated to the desired temperature in under a minute. This simple layout and ease of operation make them an advantageous choice for maintaining productivity in fast food chains, casual diners, and certain Asian restaurants.

Among all types of deep fryers in the kitchen industry, open pot fryers are particularly well‑suited for handling large batch frying tasks. They are cost‑effective and straightforward to maintain, but they do require careful temperature management to prevent oil degradation. Suppliers of open fryers often emphasize their versatility in accommodating diverse cuisines, ranging from fried chicken to seafood.

Pressure Fryers

Pressure fryers cook food by sealing it in a pressurized chamber, which speeds up the cooking process while retaining moisture. This method is renowned for achieving that crispy exterior and juicy interior, as exemplified by KFC’s original recipe chicken. The pressurized environment raises the boiling point of water, which helps to reduce frying times and lock in moisture.

However, due to the sophisticated technology involved, pressure fryers require a higher initial investment and maintenance costs. They are ideal for healthcare food services and hospital kitchens, as they can handle light-batched items like shrimp and churros with low-oil uptake and consistent texture. Modern pressure fryers come equipped with safety valves and programmable settings, with wholesale models being particularly prevalent in the QSR (Quick Service Restaurant) sector.

Countertop Fryers

Compact and space-saving, countertop fryers are well‑suited for small kitchens or businesses with limited floor space. These units are often electric, making them ideal for low‑to‑medium output tasks such as cooking appetizers or desserts. They require no gas line and are very simple to install and move.

However, as most units hold around 6 liters of oil and are designed for lower output, they are best suited for small tasks in mobile kitchens, such as those found in food trucks and pop-up snack operations.

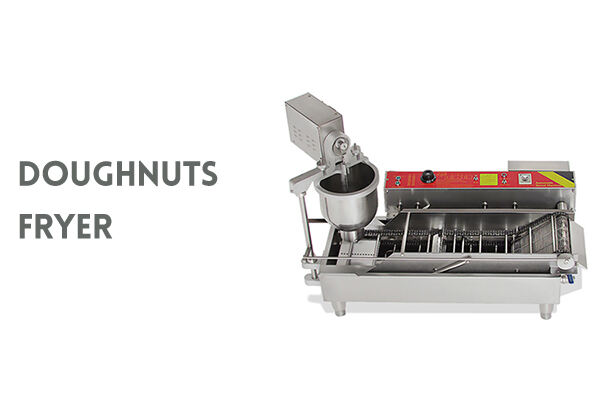

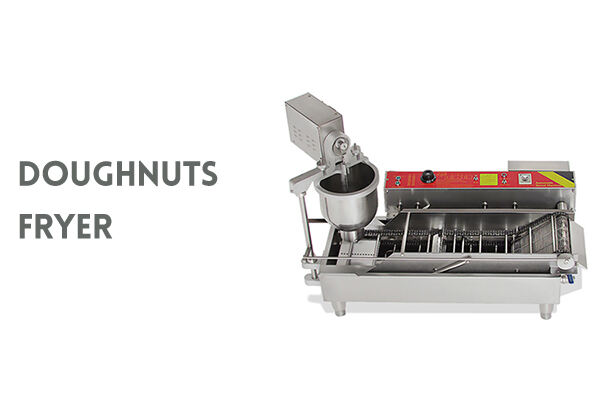

Specialty Fryers

Specialty fryers are designed to meet specific culinary needs. For example, doughnut fryers come equipped with adjustable dough guides, while tempura fryers feature fine‑tuned temperature zones. In addition to their specialized features, some specialty fryers include built-in filtration and load compensation systems to minimize debris accumulation.

These advanced features make them ideal for upscale bakeries and pastry shops that prioritize uniform appearance and moisture retention.

After-Sales:

After-Sales:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU