News

Rotary Oven: A Complete Guide for Industrial Bakery Production

If you are familiar with the commercial baking industry, especially a pastry lab or central production for a massive number of baked goods, then a rotary oven is an essential asset for your workshop. As industrial bakery ovens with stable airflow and high thermal efficiency, these units give consistent results across a trolley with multiple trays. Before picking the right rotary rack oven for your business, there is some information you need to know. In this blog, we take you through what a rotary oven is, how it works and the unique advantages.

What Is a Rotary Oven?

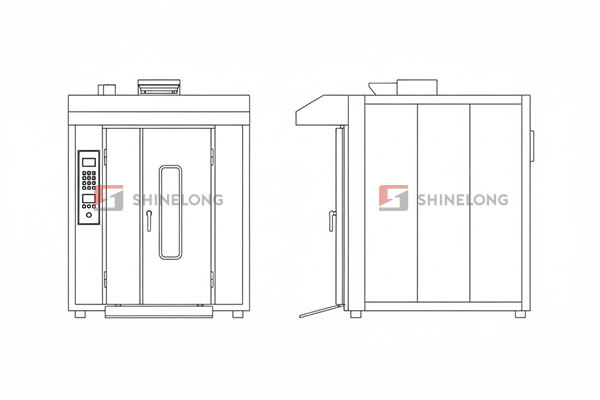

A rotary oven refers to a type of industrial baking oven designed to handle large batch production of baked goods. In simple terms, a rotary rack oven is a large baking chamber that delivers consistent and even heat distribution through a rotating trolley and a powerful air circulation system.

The operator loads numerous trays with a wide range of baked products, including cookies, puff pastry, tarts, pizza, bread, and other pastry items, onto a tall mobile trolley. Once fully loaded, the entire trolley is rolled into the oven chamber, the door is closed, and the baking cycle begins.

Here is way different than other commercial baking oven such as deck ovens or combi ovens; there is no need to rotate or replace individual trays during baking. The rotating rack ensures that every tray is exposed to the same heat conditions throughout the process. This rotating baking approach allows bakeries to finish high-volume production in a single cycle. Because of its capacity and efficiency, a rotary oven is an ideal baking solution for pastry labs, central bakery kitchens, and large-scale bakery hubs.

How Does a Rotary Oven Work?

The rotating rack inside the baking chamber is the key technology behind a rotary oven’s uniform baking performance. This rack is usually driven by a turntable mechanism located at the bottom of the oven.

During operation, the baker selects a suitable stainless steel mobile trolley, loads it with trays of baking products, and stacks them vertically inside the rack. The trolley is then pushed onto the turntable plate inside the oven and securely locked in place. Once the oven starts, the bottom turntable rotates continuously, causing the entire rack trolley to spin. This movement allows heat to reach every tray evenly from all angles.

Convection fans play an equally critical role. Multiple powerful fans inside the chamber circulate hot air throughout the oven, creating a stable thermal flow that reaches every level of the rack, from the top trays to the bottom ones, at a consistent temperature. This combination of rotation and forced convection ensures fast, even, and reliable baking results.

At SHINELONG, our rotary ovens come with an automatic warning system. If anything goes wrong, the monitor alerts you immediately so you can handle it on the spot.

Fuel Options for Commercial Rotary Ovens

When selecting the right rotary oven for your baking business, you’ve got to balance your kitchen’s requirements and initial budget. A significant part of that is picking the right fuel option.

-

Gas Option

With rapid heating and extraordinary thermal efficiency, the gas rotary oven is generally the optimal choice for most bakeries. No matter you utilize NG or LPG, it provides responsive temperature adjustments that allow the oven to return to its set temperature almost immediately after swapping the mobile trolley. Furthermore, the gas option is often significantly less expensive than electricity regarding daily operating costs. However, compared to electric models, it has minor limitations in heat distribution consistency, and the initial setup cost can be a bit of a challenge due to infrastructure requirements.

-

Electric Option

The electric rotating rack oven is more suitable for bakeries that prefer precision and a simple setup. It offers the most consistent heat distribution, making it ideal for delicate products like cakes and pastries. Because it requires no gas lines, the initial installation is straightforward and clean. The main trade-off is the operating cost, as electricity is typically more expensive than gas or diesel, leading to higher long-term expenses.

- Diesel Option

When your business is located on the area with unreliable gas and electricity. The diesel rotary oven is the ideal choice because it is able to provide powerful, intense heat that handles large batches with ease. While it is highly economical and offers total independence from the local grid, it requires more frequent maintenance to keep the burner clean and soot-free. You also need to account for the extra space required for an external fuel storage tank.

At SHINELONG, all three fuel options are available across our entire rotary rack oven series. We provide tailored baking solutions to ensure your kitchen maintains impressive productivity and performance.

What Are the Benefits of Rotary Ovens

If you are running a high-output bakery business, a rotary oven definitely is the go-to commercial baking solution. Here are 5 benefits of these units:

- Uniform Heat Distribution: The rotating rack design ensures every product is exposed to the same heat airflow. This eliminates hot spots, resulting in an even bake across the entire rack.

- Massive Productivity: By loading tall mobile trolleys with dozens of trays at once, you eliminate the need to swap individual trays manually. This allows you to finish tremendous orders in a single cycle.

- Multiple Baking Modes: It is standard for these machines to come equipped with versatile settings for different recipes. For example, the SHINELONG rack oven features specialized baking groups to help you expand your menu, including a bread mode for baked goods, a biscuit mode for cookies or crusty pastries, and even a grilling mode for poultry.

- Rapid Baking Times: Multiple powerful convection fans circulate heat throughout the entire chamber, ensuring a higher number of thermal cycles during the baking period.

- Maximum Output Without Sacrificing Quality: One of the most important advantages of a rotary oven is the ability to achieve bulk production at a consistent quality level. This consistency is vital for catering and commercial businesses that require every loaf or pastry to look and taste identical.

- Programmable controls: This is a standard feature in modern baking ovens. For example, SHINELONG rotating rack ovens allow for precise "baking curve" control. The machine follows your exact programmed settings, ensuring repeatable, amazing texture results every time you bake.

Rotary Oven vs. Other Commercial Baking Ovens

When choosing a commercial oven for your pastry business, the variety of options can be confusing. You might wonder: Is a rotary oven actually the right option for my business? To help you decide, we’ve put the rotary oven against other common bakery ovens to break down the differences.

Rotary Oven vs. Deck Oven

Deck ovens are the go-to choice for traditional artisan bread or pizza, using conduction heat through a stone sole to create a thick, crunchy bottom crust. However, they rely heavily on the chef's manual technique, requiring every loaf to be loaded and unloaded by hand.

In contrast, as long as you set the programmed curve, a rotary rack oven can bake a tremendous amount of food at once using its rotation and convection functions. While both ovens are excellent for a bakery, if you are looking for high-volume batch production, the rotary oven is definitely the way to go.

Rotary Oven vs. Combi Oven

There is no doubt that combi ovens represent the state-of-the-art in commercial cooking equipment. They offer a valuable all-in-one solution for commercial kitchens, combining convection, steam, and baking functions. This versatility allows you to cook a wide variety of foods beyond just dough-based products.

The commercial rotary oven, however, is purpose-built for massive bakery production. It features much larger chambers and a rotation mechanism that ensures even browning across dozens of trays. Despite this, the rotary oven has limitations compared to the combi oven regarding flexibility, temperature precision, and cooking process optimisation.

If you have sufficient initial capital and a spacious back-of-house, investing in two or three high-capacity commercial combi ovens may be the better solution. By installing multiple units, you can offset the capacity gap while gaining much more versatility than a single rotary oven can provide.

Rotary Oven vs. Convection Oven

Standard convection ovens use fans to distribute hot air, but the trays stay in one place. This frequently causes "hot spots" where the product closest to the fan browns faster. A rotary oven solves this by spinning the entire rack. This constant motion ensures that the airflow hits every angle of your pastries equally, eliminating the need to manually flip or rotate trays halfway through the bake.

How to Choose the Right Rotary Oven for a Pastry Business

Selecting an industrial bakery oven is a major investment that requires careful consideration. To help you make the right decision, keep these four essential factors in mind:

- Assess Your Production Volume: Before anything else, you must figure out your daily production volume. Knowing the scale of your catering service or bakery is a way to select equipment with the appropriate capacity. Choosing an oven that is too small will impact your operation efficiency, while one that is too large will lead to unnecessary energy waste.

- Evaluate Your Fuel Options: Once you have confirmed the capacity, you must decide on a fuel source. A gas rack oven is a safe choice for almost any bakery due to its efficiency and power. However, if your recipes require extremely precise temperature control, the electric option is superior. For remote areas with unreliable energy infrastructure, the diesel option remains the most dependable solution.

- Partner with a Reliable Supplier: A bakery oven is only as good as the support behind it. Ensure your supplier offers rapid customer service and a comprehensive warranty to protect your investment. At SHINELONG, our dedicated customer center is designed to resolve issues quickly—covering everything from troubleshooting and installation to accessory supply and professional maintenance guides.

- Look for Advanced Technology: Choosing a machine with modern technology will drastically improve your operational productivity. Look for features such as programmable controls, recipe memory storage, automatic temperature controllers, and integrated exhaust systems. At SHINELONG, we offer customized solutions that incorporate these advanced features to ensure your kitchen stays ahead of the competition.

Frequently Asked Questions About Commercial Rotary Ovens

1) What is a rack oven?

A rack oven is an industrial baking chamber designed for large batch production. It utilizes a rotating trolley and a powerful convection air system to bake dozens of trays simultaneously. This setup ensures that heat is delivered evenly to every item, from cookies to bread, in a single cycle.

2) Deck oven or rack oven: Which one is better for a bakery shop?

It depends on your goals. Deck ovens are the go-to for traditional artisan bread or pizza requiring a thick, crunchy bottom crust. If you want high-volume batch production and consistent quality with less manual labor, the rotary rack oven is the superior choice.

3) How does a rotary oven differ from a convection oven?

Standard convection ovens keep trays stationary, which often causes "hot spots" where the side facing the fan browns faster. A rotary oven solves this by physically spinning the entire rack. This constant motion ensures that airflow hits every angle of your pastries equally, eliminating the need to manually flip or rotate trays.

4) How to use a rotary rack oven?

Operation is straightforward: load your products onto a mobile trolley, roll it into the chamber, and lock it onto the turntable. Once the door is closed, select your programmed "baking curve" on the control panel. The oven then automatically manages the rotation, heat, and steam until the batch is finished.

5) How often does a rotary rack oven need maintenance?

To ensure long-term reliability, a rotary rack oven requires a mix of daily and professional maintenance. Daily tasks should include cleaning the interior floor and checking the door seals for leaks. On a professional level, we recommend a full technical service every half a year.

After-Sales:

After-Sales:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU