Smart Technology Integration: Precision Meets Automation

Temperature control is crucial for making bread and other baked goods. If a bakery wants to create crispy and fluffy pastries, it must pay close attention to adjusting the baking temperature. Today, the era of manual temperature adjustments and guesswork in baking is fading. Modern commercial bakery ovens now leverage intelligent programmers and AI-driven controls to optimize baking cycles. For example, Shinelong’s 900 Series Induction Cooktop uses precise temperature regulation to maintain consistent heat distribution, reducing energy waste by up to 20% compared to traditional gas models. Similarly, Shinelong’s digital control deck ovens feature independent deck timers and real-time monitoring, ensuring uniform browning for artisanal bread and pastries.

Energy Efficiency and Sustainable Design

A 2024 study by China’s Bakery Equipment Association revealed that energy-efficient ovens can lower operational costs by 18 - 22% annually. In the commercial bakery industry, sustainability is no longer optional. Manufacturers are prioritizing eco-friendly materials and energy-saving technologies. For example, Shinelong recently promoted deck ovens that incorporate off-gas treatment systems to reduce carbon monoxide emissions, aligning with global safety standards like CE. Meanwhile, some ovens focus on sustainability by eliminating the need for external exhaust systems, which can help cut energy consumption by 25% in compact kitchens.

Max Series Electric Convection Oven

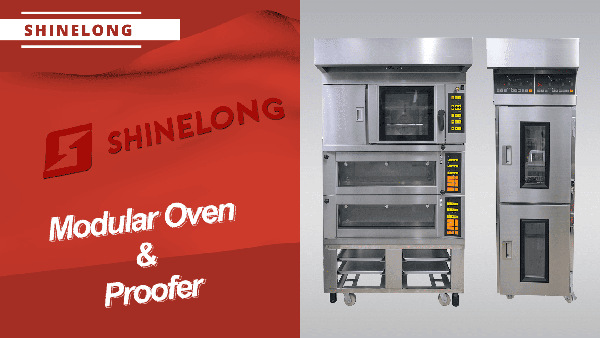

Modular and Space-Saving Solutions

Urban bakeries and bakery food trucks are emerging as new trends in the modern city. These trends demand bakery solutions that are versatile, flexible, and space-saving, allowing businesses to customize layouts without sacrificing functionality. Modular bakery systems are the ideal solution to meet these needs. Shinelong’s multi-baking kitchen designs and modular baking ovens exemplify this trend, enabling clients to fit full-scale operations into tight spaces.

Modular Kitchen Solution

Industrial-Grade Automation for High-Volume Production

Large-scale bakeries require equipment that balances speed with precision. Industrial bakery equipment, such as automated dough sheeters and proofing chambers, is revolutionizing mass production. The dough mixer, an indispensable piece of kitchen equipment in every bakery, whether in a food truck or a large-scale bakery, is no exception. Shinelong offers a comprehensive production line with a variety of capacities to meet diverse needs. In Shinelong’s bakery solutions, we can help you build fully customized bread lines

Undercounter Freezer

Enhanced Safety and Hygiene Standards

Hygiene is a non-negotiable priority in the food preparation industry. This is why stainless steel construction dominates modern kitchen designs, as seen in Shinelong’s NSF-certified mixers and high-grade kitchen installations. Additionally, touchless interfaces and self-cleaning mechanisms are gaining traction. For instance, integrating UV-C sanitization into proofing chambers eliminates microbial growth, ensuring that the baked goods you produce meet hygiene standards.

Baking Prepare

Customization and Flexibility for Niche Markets

From gluten-free bakeries to vegan patisseries, equipment must adapt to diverse dietary trends. Customizable bakery machines allow businesses to tweak settings for alternative flours or low-sugar recipes. For example, Shinelong’s Gas / Electric Hybrid Ovens can switch between energy sources, making them ideal for regions with unstable power grids. And guess what?3D-printed molds have become a hit in the gourmet bakery scene, offering bespoke shaping tools for intricate pastry designs.

Bakery Kitchen Solution

Data-Driven Maintenance and Predictive Analytics

Proactive maintenance is critical for minimizing downtime, especially in large-scale bakeries. Data-driven predictive analytics can predict equipment malfunctions and help bakeries save costs. Nowadays, smart ovens are transmitting performance data to cloud systems, predicting component failures weeks in advance. These innovations are popping up in the market. In conclusion, data-driven technology isn't just for our mobile phones or office laptops. It can revolutionize kitchen equipment, helping bakery kitchens step into a brand-new generation.

Data-Driven Analytics

Revolutionize Your Bakery Equipment Right Now

Modern bakery equipment innovations are not just about faster ovens or bigger mixers—they represent a holistic reimagining of the commercial kitchen. By embracing smart technology, sustainability, and flexibility, businesses can stay competitive in a rapidly evolving market. Whether you’re a boutique bakery or an industrial producer, investing in these advancements is key to delivering quality, efficiency, and profitability. Explore cutting-edge solutions from Shinelong to transform your bakery operations today.

FAQs

1. What modular solutions work best for small bakery spaces?

For compact kitchens, prioritize stackable bakery systems like vertical spiral mixers or ventless ovens. Modular designs also allow future expansion without overhauling your layout.

2. How do IoT-enabled commercial bakery ovens improve efficiency?

IoT-enabled commercial bakery ovens use sensors and cloud-based analytics to monitor baking cycles in real time. They automatically adjust temperature, humidity, and airflow based on recipe requirements, reducing human error and energy waste.

3. Are energy-efficient bakery machines worth the investment?

Absolutely. Energy-efficient industrial bakery equipment, like ventless ovens and solar-powered mixers, significantly reduces utility bills.

After-Sales:

After-Sales:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU