News

NOT ONLY PROVIDE A FINE DINE RESTAURANT KITCHEN

Integrating Commercial Kitchen Design with Operational Efficiency

The Role of Comprehensive Kitchen Engineering in High-Performance Restaurants

Leading commercial kitchen engineering firms now prioritize workflow optimization as a non-negotiable design principle. Research shows kitchens with sequential workstation layouts reduce cross-traffic by 52% during peak hours, enabling chefs to maintain consistent culinary output while minimizing motion waste. This systematic approach integrates three operational pillars:

- Ergonomic equipment spacing (minimum 1.1m between stations)

- Strategic sightlines between prep and cooking zones

- Real-time performance monitoring through IoT sensors

Balancing Aesthetics and Functionality in Premium Kitchen Spaces

Fine dining restaurants today need kitchens that blend practical stainless steel elements with some real architectural flair. Take frosted glass partitions as an example they cut down on visual mess without compromising most of the cleanliness requirements. We're seeing something interesting happening with open kitchen concepts lately. These so-called chef theaters let diners watch the action happen right in front of them. And guess what? The fancy stuff works better too. Antimicrobial copper surfaces look great but also make cleaning easier for staff, which helps maintain those high hygiene standards while still looking posh.

Data-Driven Approach to Kitchen Performance Optimization

Kitchen analytics platforms now track 18+ operational metrics, from average dish assembly time (target: 4.2 minutes) to refrigeration energy consumption patterns. A 2023 study of 120 Michelin-starred kitchens revealed establishments using predictive maintenance systems reduced equipment downtime by 37% compared to traditional reactive models.

Core Principles of Workflow-Centric Kitchen Layouts

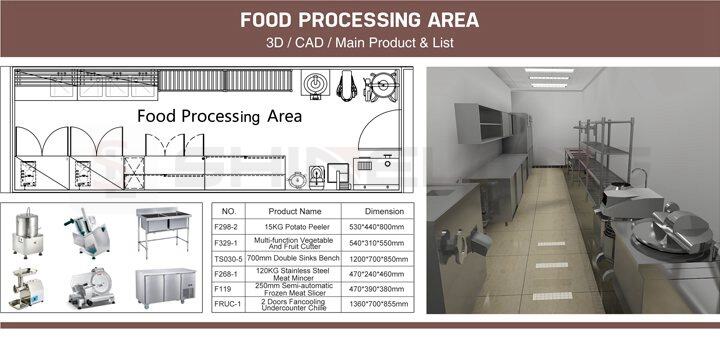

- Zonal Segmentation — Defined cold/hot processing areas prevent cross-contamination

- Capacity Matching — Prep surface allocation proportional to menu item complexity

- Future-Proof Modularity — 20% reserve space for equipment upgrades

- Safety Buffers — 400mm clearance zones around all high-heat appliances

This framework enables restaurants to achieve 86% faster service speeds without compromising safety standards, according to hospitality operations analysts.

Optimizing Kitchen Workflow Through Strategic Zoning and Layout Design

Zoning for Cooking, Prep, and Cleaning Areas to Enhance Flow

Most commercial kitchens these days use smart engineering approaches to sort their workflow areas into three main sections: the hot zone for cooking, the cold area for prep work, and the wet section where cleaning happens. Restaurants that set things up this way see much less back and forth between staff members. According to research from the National Restaurant Association in 2023, kitchens organized like this cut down on employee movement by about 38% compared to older open floor plans. There's also something called the work triangle concept that restaurant designers talk about all the time. Basically, it means placing cooking stations, prep tables, and storage spots so they're comfortably reachable from each other. This creates smoother paths through the kitchen when things get busy. Operators who plan their kitchen spaces carefully often find their meal prep goes significantly quicker too. One survey showed meal assembly speeds improved around 22% because everything was positioned better and ingredients were ready to go where needed.

Improving the Flow of Materials and Personnel Through Smart Design

High-performance kitchens use angled equipment arrangements and anti-fatigue flooring to streamline staff rotations. Vertical storage keeps tools accessible without clutter, while color-coded plating stations reduce cross-contamination risks.

Case Study: Reducing Plate Delay by 30% via Layout Restructuring

A Michelin-starred restaurant increased dinner service capacity by 18% after redesigning its expo line. By relocating the pastry station 4 meters closer to dishwashing and installing an overhead rail system for sauce finishing, chefs eliminated 47 unnecessary steps per entrée.

Maximizing Space Efficiency Without Sacrificing Safety or Speed

Multifunctional equipment like combination ovens with integrated blast chillers allows compact kitchens to maintain diverse menus. Roll-out shelving beneath workstations provides 27% more storage without impeding fire exits, complying with NFPA safety standards.

Equipment Selection and Scalable Design Aligned with Culinary Demand

Essential Kitchen Equipment Selection Based on Menu Complexity

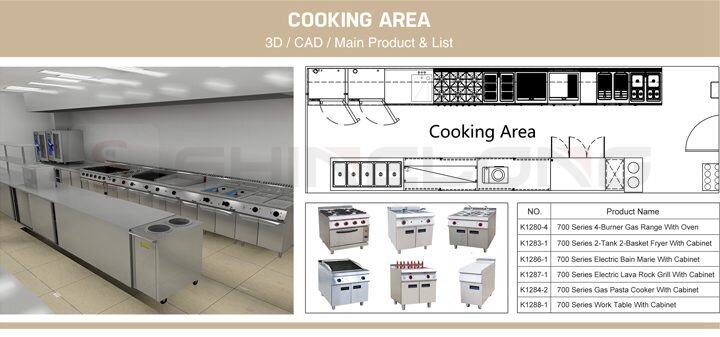

Equipment selection should align precisely with menu demands. Molecular gastronomy operations require 30% more specialized tools—such as vacuum sealers and precision cookers—than traditional fine-dining kitchens. Multipurpose appliances like combi-ovens reduce footprint by 18% while supporting roasting, baking, and sous-vide functions.

Matching Equipment Capacity to Peak Hour Throughput

Data-driven planning prevents service bottlenecks:

- Grill stations should handle 12—15 covers/hour per chef in steakhouse settings

- Fryers must manage 50—60% higher batch volumes during weekend peaks

- Dishwashers need 45-second cycle times to sustain flow during 300+ cover services

Oversized units increase energy costs by 22%, while undersized ones risk $740/hour in lost revenue during peak demand.

Modular and Scalable Designs for Evolving Culinary Needs

Seventy-four percent of restaurants upgrade key equipment within three years due to poor scalability (Leading Catering Systems 2023). Forward-thinking designs include:

- Mobile cooking stations with standardized utility hookups

- Stackable refrigeration units that expand cold storage seasonally by 40%

- Reconfigurable prep surfaces with interchangeable attachments

This modular approach cuts reconfiguration costs by 40% when adapting to menu changes or expanded service models. Leading suppliers now offer systems with under 12-hour changeover capabilities, far quicker than traditional 3—5 day installations.

Safety, Hygiene, and Regulatory Compliance in Fine Dining Kitchens

Comprehensive kitchen engineering ensures safety protocols prevent operational shutdowns while maintaining seamless service.

Ventilation and Fire Safety Systems as Non-Negotiable Elements

High-performance kitchens require ventilation systems that remove 85—90% of airborne contaminants hourly. Fire suppression systems such as automated Ansul units must meet NFPA 96 standards, with hoods designed to keep grease levels below 0.5g/m³ (ScienceDirect 2017). Proper placement of gas shutoff valves and heat sensors reduces fire response times by 40%.

Meeting Safety and Health Compliance in Kitchens

Kitchens using digital HACCP monitoring tools achieve 98% audit compliance rates. Critical benchmarks include:

Compliance Metric |

Standard |

Impact |

Surface sanitization frequency |

FDA Food Code §4-602.11 |

73% reduction in cross-contamination |

Hood inspection intervals |

NFPA 96 §11.6 |

60% lower fire incidents |

Food storage temperatures |

FSMA 21 CFR §117.3 |

82% fewer safety violations |

Ease of Sanitation Through Strategic Surface and Layout Planning

Hygienic design—such as seamless stainless-steel junctions and sloped floor drains—reduces bacterial colonization by 70%. Workstations with less than 1cm gaps between appliances minimize food buildup, cutting nightly cleaning labor by 25%.

Frequently Asked Questions

What is the significance of ergonomic equipment spacing in commercial kitchen design?

Ergonomic equipment spacing, maintaining at least 1.1 meters between stations, is crucial for workflow optimization. It reduces cross-traffic, minimizes motion waste, and enables chefs to maintain consistent culinary output during peak hours.

How do modern kitchens balance aesthetics and functionality?

Modern fine-dining kitchens blend practicality, like stainless steel, with architectural flair. Using frosted glass partitions or antimicrobial copper surfaces enhances cleanliness and hygiene without compromising visual appeal.

What are essential principles in workflow-centric kitchen layouts?

Principles include zonal segmentation to prevent cross-contamination, capacity matching based on menu complexity, future-proof modularity for equipment upgrades, and safety buffers around high-heat appliances.

Why is a modular approach important in kitchen design?

A modular approach allows flexibility, reduces reconfiguration costs, and accommodates evolving culinary needs by including mobile cooking stations and stackable refrigeration units.

After-Sales:

After-Sales:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU