News

3 Types of Ice Maker Condensers: Air-Cooled, Water-Cooled & Remote-Cooled

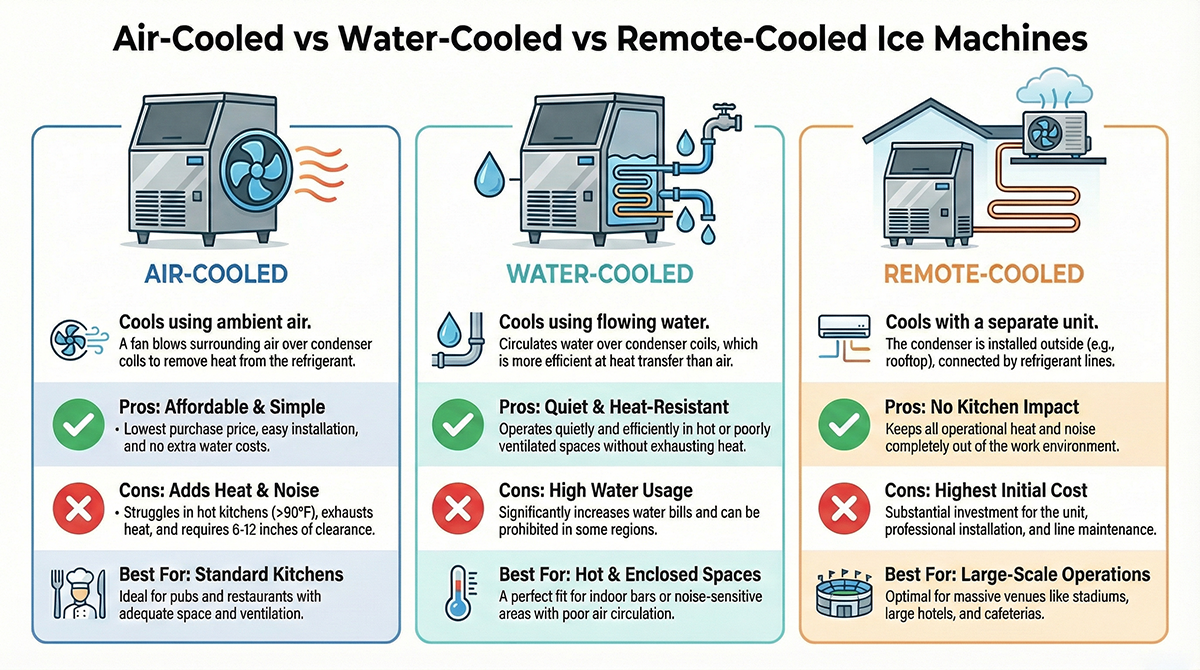

When you head to purchase a commercial ice maker machine, there are always three options: air-cooled, water-cooled, and remote-cooled ice machines. So, what’s the difference between these types of condensers, and how will they impact your foodservice location? I bet this question is messing with your decision. In this guide, we’ll walk you through the definitions, pros, cons, and applications of these three types of ice machines to help you avoid costly mistakes.

Air-Cooled Ice Machines

An air-cooled ice maker machine is typically the most common ice solution across commercial foodservice settings. In an air-cooled condenser system, refrigerant is pumped through the condenser coils while a built-in fan pulls in ambient air and blows it across the coils. This airflow removes heat from the refrigerant, allowing it to cool down before circulating back to the evaporator plate to form ice.

Because the system relies on the surrounding air to release heat, proper distance and ventilation are essential. Leaving enough space around the ice machine ensures stable performance, consistent ice production, and prevents heat buildup in the back of the house.

Pros of Air-Cooled Ice Machines

- The most affordable option to purchase, making it fit in most foodservice locations.

- Easy to install and maintain, with no complicated setup requirements.

- No additional operating costs, such as extra water consumption, which helps control utility expenses.

Cons of Air-Cooled Ice Machines

- Struggles in high ambient temperatures, especially when kitchen temperatures exceed 90°F (32°C).

- Exhausted heat is released back into the kitchen, raising back-of-house temperatures, and the fans can create consistent operating noise.

- Requires sufficient clearance (typically 6–12 inches) around the unit to ensure proper airflow and heat exchange.

Best Applications for Air-Cooled Ice Machines

Air-cooled ice machines are the most popular and widely used option across many premises, including pubs, quick-service restaurants, and dining facilities. If you choose an air-cooled model, it’s important to ensure there is enough installation space and reliable ventilation to maintain stable performance and avoid overheating issues.

Water-Cooled Ice Machines

Water-cooled condensers use flowing water to remove heat from the condenser coils, instead of relying on pulling in surrounding ambient air. Because water has a much higher heat transfer efficiency than air, it can pull heat away from the refrigerant quickly and consistently. This allows the ice machine to maintain stable operating temperatures even in hot environments typically more than 90℉, while the heated water is discharged directly through the drain.

Water-cooled ice machines are an ideal solution for locations with high ambient temperatures, limited ventilation, or noise-sensitive areas, such as departure lounges, indoor bars, and enclosed foodservice spaces.

Pros of Water-Cooled Ice Machines

- One of the advantages of a liquid-cooled machine is that it can operate in a hot environment.

- It would not exhaust out extra heat and it's great for the room without air conditioning.

- Without a condenser fan, these units are significantly quieter.

Cons of Water-Cooled Ice Machines

- The biggest drawback is high water consumption, which directly increases daily operating costs.

- Water quality requirements are critical. In areas with hard water, minerals such as calcium and magnesium can build up inside the water jacket. Over time, this mineral scale forms an insulating layer that reduces heat transfer efficiency and can put excessive strain on the compressor.

Best Applications for Water-Cooled Ice Machines

In summary, water-cooled ice machines are a perfect solution for high-ambient environments without air conditioning or ventilation. However, the trade-off is significantly higher water usage. For example, a 300 lb water-cooled ice machine can increase your monthly water bill by around $40, depending on local rates. In some regions with strict water conservation regulations, water-cooled ice machines may even be restricted or prohibited due to excessive water consumption.

Remote Condenser Ice Machines

The third option is a remote condenser ice machine. This design separates the condenser from the ice maker itself, with the condenser typically installed on the rooftop or exterior wall. The two components are connected by refrigerant lines. A big fan inside the remote condenser pulls in ambient air through it and cools it down.

Because the condenser is located away from the kitchen, this setup keeps heat and operating noise out of the workspace, creating a comfortable and quieter environment for staff. That’s why remote-cooled ice machines are often chosen for high-end restaurants, hotels, and facilities where comfort and noise control matter.

However, a remote condenser system is usually the most expensive option among the three types. It requires purchasing an additional condenser unit, hiring professional technicians for installation, and allowing extra budget for maintenance and repairs. This means the upfront investment for a remote-cooled ice machine is extremely substantial.

Pros of Remote-Cooled Ice Machines

- With a separate design, the condenser is installed away from the workstation, creating a quiet and comfortable zone for staff.

- No need to use a bunch of extra water but remain energy efficient.

- Running several ice makers into one condenser rack system.

Cons of Remote-Cooled Ice Machines

- The initial investment is extremely substantial.

- Have to deal with extra Maintenance and repair of refrigerant lines.

Best Applications for Remote-Cooled Ice Machines

The optimal option for massive stadiums, large hotels, and 800+ diner cafeterias, where the cumulative heat and noise of multiple machines would be unbearable.

Air-Cooled vs Water-Cooled vs Remote-Cooled Ice Machines

In short, selecting the appropriate Ice maker machine for a foodservice location is a tricky task. So we have compiled key information about these 3 different types of condensers into one image to explain how to make a reliable decision in the initial buying process.

After-Sales:

After-Sales:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU