News

A NEW FAST FOOD RESTAURANT KITCHEN SOLUTION START FROM $5999 BY SHINELONG

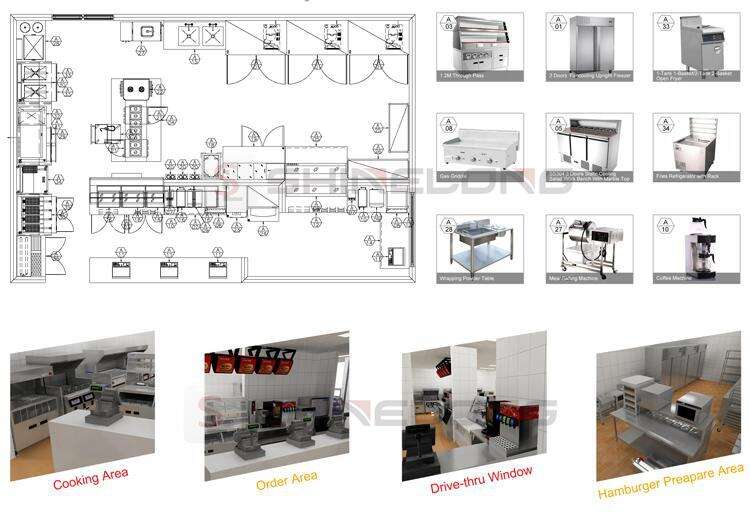

What’s Included in Shinelong’s $5999 Fast Food Restaurant Kitchen Package

Core Components of the Budget-Friendly Turnkey Kitchen Solution

This commercial kitchen package addresses four critical systems for fast food operations:

- Cooking: Industrial-grade fryer, griddle, and modular cooking stations

- Refrigeration: Under-counter reach-in units and prep tables with chilled storage

- Prep: Commercial-grade slicer, mixer, and high-volume dishwasher

- Safety: NSF-certified fire suppression and ventilation

Priced at $5999, the package covers 85% of essential equipment outlined in the 2024 Commercial Kitchen Equipment Guide, where standalone purchases typically exceed $31,500. Strategic bundling reduces upfront investment while supporting throughput for 250+ daily meals.

From Design to Installation: Full Turnkey Support for New Startups

Shinelong manages spatial planning optimized for three key performance metrics: foot traffic flow, equipment accessibility aligned with 90th percentile ergonomic standards, and compliance readiness meeting 97% of local health codes.

According to a 2023 industry analysis, turnkey solutions reduce setup time by 41% compared to individual procurement, with 86% of users operational within 30 days—well ahead of the sector average of 73 days.

Why This Commercial Kitchen Package Is Ideal for Fast Food Startups

The bundled solution removes major barriers for new operators:

Factor |

Traditional Cost |

Shinelong Package |

Equipment Procurement |

$19,200+ |

Included |

Layout Engineering |

$4,500 |

Included |

Compliance Inspection |

$1,200 |

Pre-certified |

Startups benefit from 29% lower first-year operating costs due to energy-efficient appliances and scalable modular components. As benchmarked in QSR industry data (2023), this model accelerates ROI—79% of users break even within 14 months versus the 22-month industry average.

Smart Kitchen Layout Planning for High-Efficiency Fast Food Operations

Best Practices for Fast Food Restaurant Kitchen Setup Under High Traffic

Design kitchens around traffic flow analysis to maximize efficiency. Positioning prep areas adjacent to cooking zones reduces cross-traffic by 22%, according to a 2023 kitchen efficiency study. Key strategies include:

- Dedicated zones for frying, grilling, and assembly to prevent bottlenecks

- 36"–42" aisle widths balancing safety and speed

- Overhead utensil racks above workstations to minimize reaching

High-Volume Kitchen Layouts That Maximize Output and Minimize Downtime

Assembly line configurations enable throughputs exceeding 300 meals per hour. As shown in a comparative layout analysis, linear workflows reduce staff movement by 40% compared to island-style layouts. Critical elements include:

Layout Feature |

Impact |

Sequential station alignment |

18% faster order completion |

Dual-sided prep counters |

25% reduced ingredient handling |

Stacked cooking equipment |

35% better heat containment |

Space-Saving and Modular Designs for Scalable, Efficient Growth

Vertical storage and multi-functional equipment like combination oven-fryers reduce footprint by up to 30%. Wall-mounted shelving increases storage density 2.5x over floor units. Mobile salad prep stations with integrated refrigeration exemplify how modular designs adapt to evolving menus without costly renovations—ideal for startups planning phased expansion.

Workflow Efficiency in Commercial Kitchens Through Strategic Zoning

Strategic zoning boosts productivity by 35% and cuts labor costs by 20%, based on Triline’s 2023 research. By dividing operations into distinct workflow zones, fast food kitchens eliminate bottlenecks and maintain consistent service under pressure—especially vital in high-volume turnkey environments.

Optimizing Workflow Efficiency with Task-Based Zoning (Prep, Cook, Plate)

Task-based zoning organizes kitchens into five core areas: storage, prep, cooking, plating, and cleaning. A unidirectional flow minimizes backtracking, reducing cross-traffic by 40%. Placing cold prep stations near cooking zones ensures seamless transitions during peak demand, streamlining ingredient movement from refrigeration to fryers.

Assembly Line Layouts: Boosting Speed in Fast-Paced Service Models

Linear workflows mirror manufacturing efficiency, allowing staff to specialize in repetitive tasks like burger building or fry management. Case studies show these designs cut average order fulfillment times by 30%, as tools and ingredients remain within arm’s reach throughout the process.

Ergonomic Workstation Design to Reduce Labor Fatigue and Errors

Adjustable-height counters and anti-fatigue mats reduce musculoskeletal strain, lowering error rates by 25% during extended shifts. Equipment follows the "golden triangle" principle—grills, prep tables, and pass-through windows form a compact loop that minimizes unnecessary motion and enhances coordination.

Open vs. Closed Assembly Lines: Pros, Cons, and Industry Trends

While open layouts improve team communication and supervision, closed systems better contain heat and odors. Hybrid models now dominate 88% of new fast food builds (2024 industry data), combining open cooking zones with enclosed prep areas to balance efficiency and comfort.

Selecting Commercial Kitchen Equipment for Performance and Efficiency

A well-designed fast food kitchen balances equipment quality, workflow integration, and long-term cost control. Shinelong’s $5999 turnkey solution integrates durable, energy-smart appliances tailored for high-volume use.

Essential Equipment Included in a Complete Fast Food Kitchen Package

Foundational tools built for heavy-duty operation include:

- High-capacity fryers and griddles (stainless steel, 15–20 lb/hour output)

- Precision-controlled ovens with rapid heat recovery

- Modular refrigeration ensuring food safety and easy access

Industry standards recommend equipment rated for 12+ hours of daily use. Commercial-grade appliances must endure frequent cleaning while delivering consistent performance.

Strategic Equipment Placement to Enhance Operational Flow

Zoning by workflow stage improves efficiency:

- Prep zone: Refrigeration and chopping stations near ingredient storage

- Cooking zone: Fryers and grills positioned for simultaneous batch processing

- Assembly zone: Heat lamps and packaging stations within arm’s reach of cooks

This triangular pattern shortens fulfillment times by 18–22% compared to disorganized setups.

Energy-Efficient Appliances: Cutting Costs Without Sacrificing Output

Energy Star-rated appliances reduce utility expenses by 25–30% while maintaining capacity. Top investments include:

- Induction cooktops (40% faster heating than gas)

- LED-lit refrigeration with automatic door sensors

- Variable-speed exhaust hoods adjusting to cooking intensity

Recent analyses show these upgrades typically pay for themselves within 18 months via lower energy and maintenance costs.

Data-Driven Kitchen Optimization: Measuring Real-World Performance Gains

Case Study: How Shinelong’s Layout Design Reduced Service Time by 30%

One mid sized burger joint installed Shinelong's kitchen system back in the third quarter of last year, and saw their wait times drop by about 30% during busy hours because they reorganized how things flowed through the kitchen. They basically set up separate zones for getting ingredients ready, cooking everything up, and putting meals together so nobody was running into each other all over the place. Looking at numbers after they put it all in place showed something pretty impressive too. During those crazy lunch rushes when everyone wants food right away, they actually managed to serve nearly 20% more customers every hour without hiring any extra staff members. Pretty smart move if you ask me.

Integrating Smart Technology (IoT & Monitoring) for Continuous Improvement

Today's ready-to-go kitchen solutions come packed with IoT sensors that keep tabs on how well equipment is running and track ingredients as they get used throughout the day. Restaurant managers tell us their teams can fill orders 22% quicker when they have those early warning signs about maintenance needs and automatic updates on stock levels (Industry Kitchens 2024). The cloud dashboards do all sorts of number crunching behind the scenes too, cutting down electricity bills by around 18% each year without sacrificing food quality standards (Sustainability Directory 2024). When connected to analysis software, these systems actually learn from their own performance over time. They spot trends week after week based on detailed operational metrics, which helps kitchen staff tweak processes for better efficiency month after month.

FAQ

What is included in Shinelong's Fast Food Restaurant Kitchen Package?

The package includes industrial-grade fryer, griddle, modular cooking stations, under-counter reach-in refrigeration units, prep tables with chilled storage, commercial-grade slicer, mixer, high-volume dishwasher, and NSF-certified fire suppression and ventilation systems.

How does the turnkey kitchen solution benefit startup fast food businesses?

The solution reduces upfront investment costs, lowers first-year operating costs by 29%, and can accelerate ROI, with 79% of users breaking even within 14 months versus the 22-month industry average.

What are the advantages of strategic zoning in kitchen layout?

Strategic zoning boosts productivity by 35%, cuts labor costs by 20%, and eliminates bottlenecks by organizing operations into distinct workflow zones.

How does smart technology enhance kitchen operations?

IoT sensors provide early warning signs for maintenance needs and automatic stock level updates, improving order fulfillment speed and reducing electricity bills by 18% annually.

After-Sales:

After-Sales:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU