News

THE FULL SET OF DESIGN OF CENTRAL KITCHEN

Core Principles of Central Kitchen Overall Design

Understanding the core principles of central kitchen design

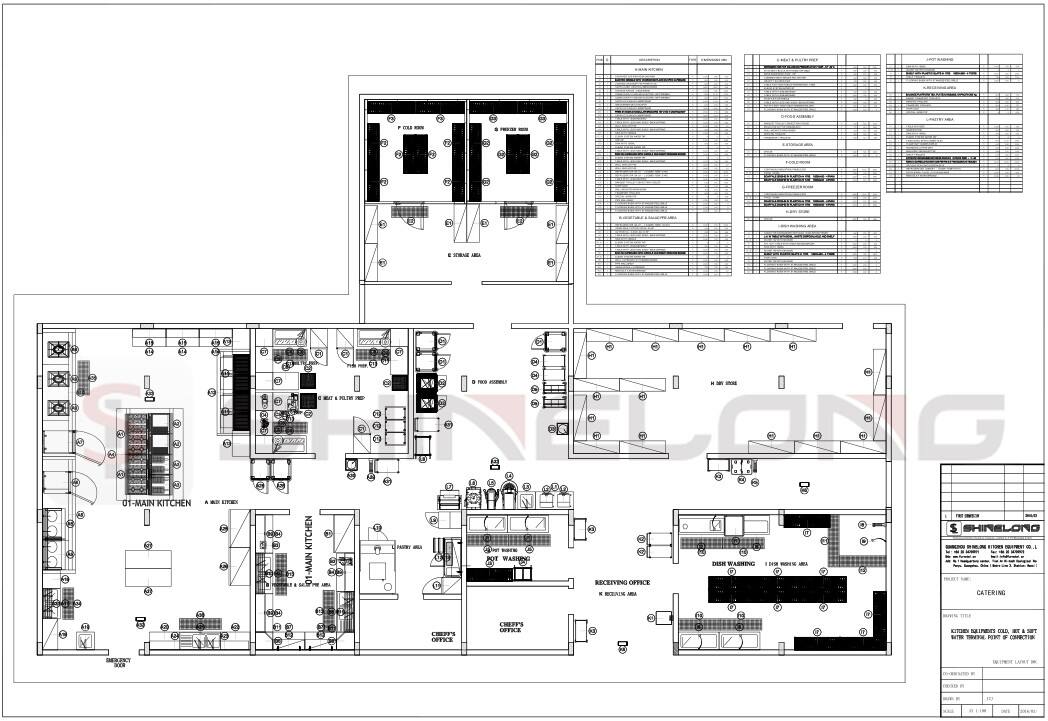

Effective central kitchen design optimizes workflow to minimize staff movement while ensuring food safety through strategic zoning. According to the 2024 Commercial Kitchen Design Report, kitchens following these principles achieve 18-22% faster prep times. Key elements include:

- A linear workflow from receiving to dispatch

- Dedicated sanitation zones with non-porous, stainless steel surfaces

- Scalable infrastructure supporting 20-30% future capacity growth

Balancing functionality, safety, and scalability in design

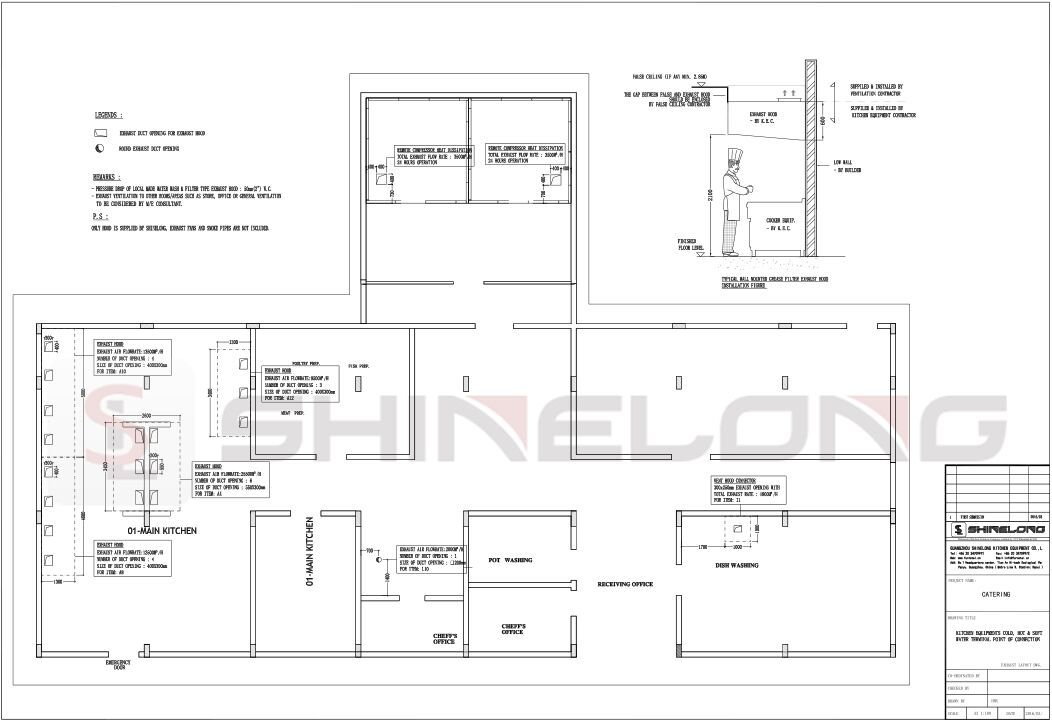

Today's central kitchens are designed with worker comfort, safety standards, and flexibility in mind. Most work areas have at least 36 inches of space between machines so staff can move around safely without bumping into things. Some facilities even install smart ventilation systems that adjust automatically when multiple appliances are running simultaneously, keeping the air fresh throughout busy service periods. The real game changer though comes from modular power setups. These allow kitchen managers to rearrange roughly two-thirds of their cooking equipment in just under two days time. This means restaurants can easily switch layouts for holiday specials or daily menu items without tearing down walls or doing expensive rewiring, yet still meet those strict food safety regulations everyone keeps talking about.

Integrating Commercial Kitchen Engineering standards

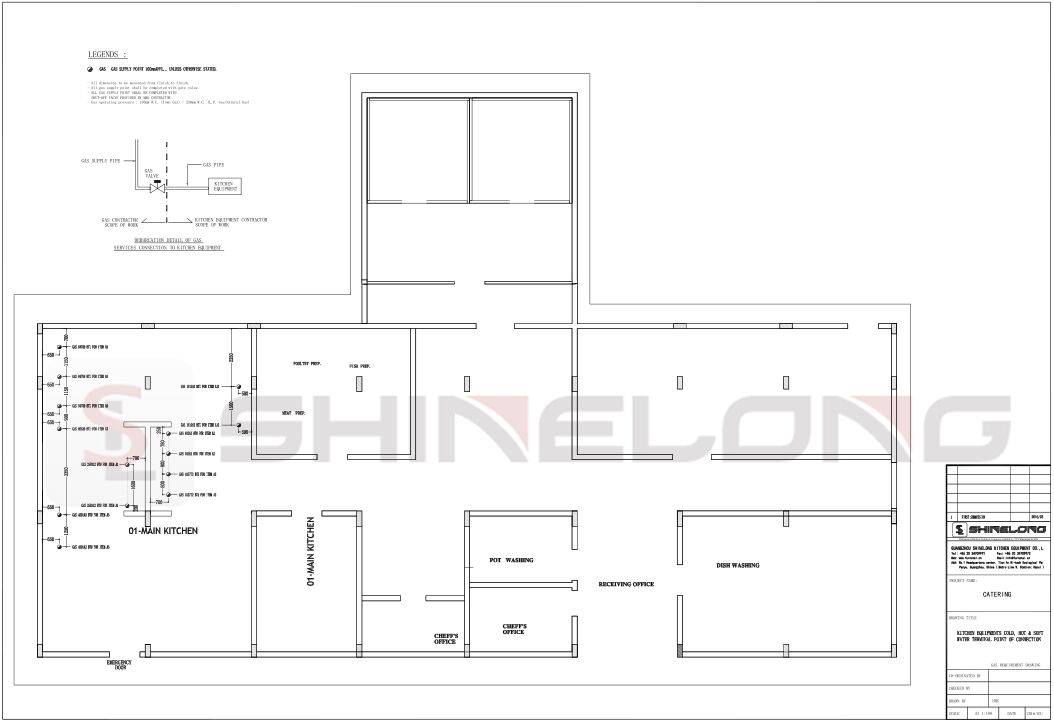

Compliance with NSF/ANSI 4 for food equipment and ISO 22000 for food safety management is essential. A 2023 FDA study found compliant kitchens reduced cross-contamination incidents by 41%. Critical engineering specifications include:

- 18-24" clearance around cooking appliances for heat dissipation and access

- Floor slopes of ¼" per foot to direct drainage toward floor drains

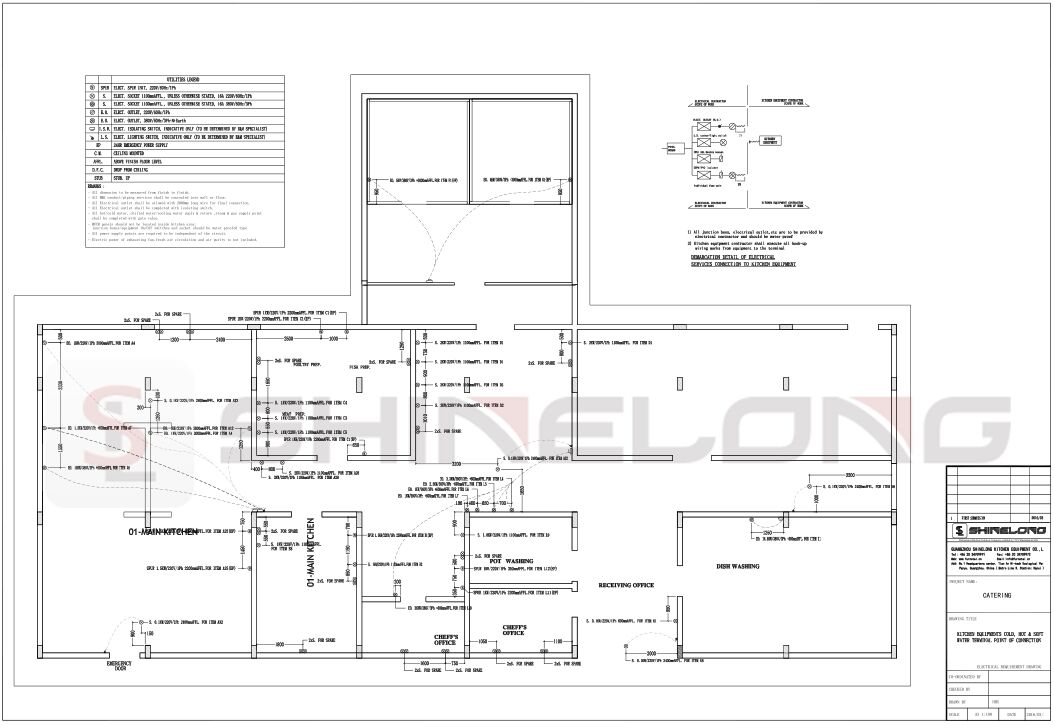

- Dedicated 240V circuits for high-load equipment like combi ovens

The role of Catering Service Facility Planning in layout efficiency

Strategic planning significantly improves operational speed. Cornell University's 2024 foodservice study found that optimized layouts reduce meal assembly time by 33% in high-volume operations. Key strategies include placing blast chillers within 15 feet of packaging stations and allocating 30% of floor space to cold chain storage—ensuring consistency across multi-location networks.

Optimizing Kitchen Layout for High-Volume Foodservice Operations

Key considerations for high-volume foodservice design

Efficient central kitchen design centers on workflow optimization, regulatory compliance, and long-term adaptability. Minimizing travel distance between work zones, separating raw and cooked food areas, and maintaining logical adjacencies—such as placing prep stations near cooking units—are critical for throughput and safety.

Linear, island, and zonal layouts: A comparative analysis

Three primary configurations dominate institutional kitchen design, each suited to different operational models:

Layout Type |

Best For |

Space Efficiency |

Flexibility Score* |

Linear |

Batch production |

92% |

Low |

Island |

Collaborative prep |

78% |

Medium |

Zonal |

Multi-concept operations |

85% |

High |

*Based on Catering Service Facility Planning Institute metrics (2023)

Island layouts, as seen in high-efficiency kitchens, reduce ingredient transfer distances by 30% through centralized equipment placement, enhancing collaboration and reducing congestion.

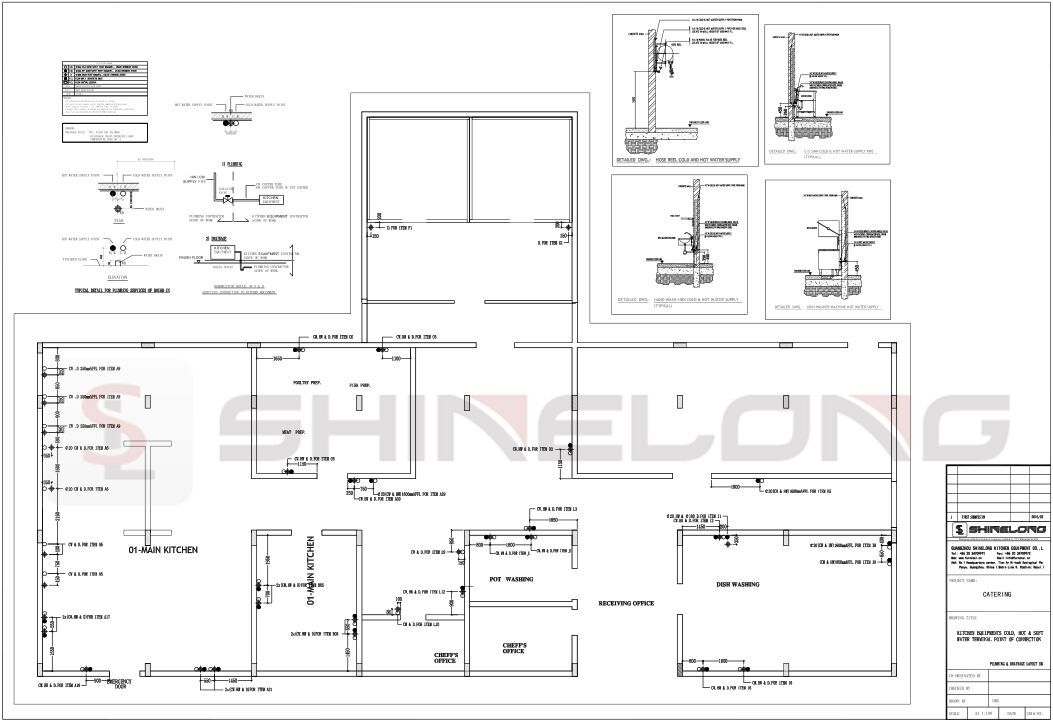

Case Study: Modular layout solutions by Guangzhou Shinelong Kitchen Equipment Co Ltd

A central kitchen serving 5,000 meals daily achieved a 40% increase in throughput using modular work cells. Retractable partitions and mobile cooking stations allowed quick transitions between banquet and à la carte production modes, maintaining workflow continuity while adapting to demand fluctuations.

Strategic Equipment Placement and Space Utilization

Placing Equipment Based on Workflow and Usage Frequency

When setting up kitchen equipment, it makes sense to match where things go with how often they get used and what steps happen when. The really busy stuff like combination ovens and those big chillers that freeze food fast? They need to sit right next to where staff prepare ingredients so nobody has to run back and forth all day long. Things that don't see much action most days can hang out on the edges somewhere. Take a look around commercial kitchens that actually work well - studies point to something interesting happening there. Kitchens designed this way cut down on people bumping into each other while moving between stations by about 28 percent according to research. Less crossing paths means fewer accidents and smoother operations overall for everyone involved in food service.

Maximizing Space Efficiency in Compact Central Kitchens

For kitchens smaller than 1,000 square feet, getting creative with equipment makes all the difference. Think about combo steamers that can roast too, or those handy tilt skillets that do away with needing several separate appliances. When floor space is at a premium, vertical storage becomes a lifesaver. Hanging pot racks on walls and mounting utensils vertically can free up roughly 15 to 20 percent of precious floor area according to industry estimates. Another smart move? Installing ductless hoods above island cooking stations instead of traditional overhead systems. These modern alternatives cut down on installation expenses and keep valuable headroom intact without sacrificing proper ventilation.

Designing Modular and Scalable Systems for Future Growth

Kitchen systems built in modular fashion with standard utility hookups can be rearranged within just 4 to 6 hours, which beats out the usual 3-day process for traditional retrofits by a long shot. According to some plant efficiency studies we've seen lately, kitchens that switch to these modular setups manage to handle menus that are around 34 percent more complex without needing extra space. The flexibility comes from things like mobile refrigeration units and work tables equipped with locking casters, allowing staff to tweak layouts every single day based on what's needed for production that particular shift.

Designing Flexible Layouts for Evolving Foodservice Demands

Adaptable Kitchen Layouts in Modern Central Foodservice Facilities

Central kitchens these days need to find that sweet spot between getting things done quickly and being able to pivot when needed. Many are turning to modular workstations grouped together and equipment areas that can be moved around easily. When menus change or customer demand fluctuates, this setup makes it much simpler to rearrange without wasting time. According to recent research from the Foodservice Flexibility folks in 2025, kitchens that incorporate fold-away prep tables along with those magnetic connectors for utilities save about half the time typically spent on reorganizing compared to traditional fixed arrangements. These flexible layouts not only comply with standard commercial kitchen engineering requirements but also help operations grow as needed. Looking at another study from last year's Modular Kitchen Innovations report, we see retractable shelves and those big roll in combination ovens really making a difference in how efficiently space gets used, especially important for places churning out more than a thousand meals every day.

The Rise of Reconfigurable Stations in Institutional Kitchen Solutions

More and more institutional kitchens are now using mobile workstations that come with quick connect/disconnect utilities. These setups let staff create temporary frying zones or bulk prep areas within about 15 minutes all while keeping things clean. The real benefit comes through in places like hospitals and schools where the number of meals needed can change day to day. When kitchen equipment isn't tied down to fixed plumbing and power sources, it gives operators much more freedom to adjust how much they produce without breaking the bank on expensive renovations. For facilities watching their budgets closely, this kind of adaptability makes a huge difference when dealing with unpredictable demand fluctuations.

FAQ Section

What is a central kitchen?

A central kitchen is a large-scale food preparation facility that supports restaurants and catering operations, optimizing production and ensuring food safety.

Why are modular layouts beneficial for central kitchens?

Modular layouts offer flexibility in equipment arrangement, allowing quick adaptability to menu changes and demand fluctuations without extensive renovations.

How do smart ventilation systems enhance kitchen safety?

Smart ventilation systems automatically adjust based on active appliances, ensuring a fresh airflow and reducing risks of heat-related safety issues.

After-Sales:

After-Sales:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU