أخبار

أفضل مواد سطح طاولة العمل للمطابخ التجارية | قارن بين الفولاذ المقاوم للصدأ، الخشب، الرخام، والبولي

ما هو منضدة عمل المطبخ التجاري؟

كما هو ضروري اثاث المطبخ لتحضير الطعام، والتغليف، والمهام الخلفية المختلفة، يتم تصميم مناضد العمل في المطابخ التجارية لتحمل الاستخدام المتكرر، والدرجات الحرارية الشديدة، والمتطلبات النظافة الصارمة.

لا شك أن الفولاذ المقاوم للصدأ يظل المعيار الذهبي لأسطح الطاولات، حيث يوفر مقاومة استثنائية للتآكل والنمو البكتيري والضرر الكيميائي. إن سطحه غير المسامي يجعله مثاليًا للاتصال المباشر مع اللحوم النيئة والمكونات الحمضية ومهمات التحضير الصعبة الأخرى. والأهم من ذلك، تلعب سهولة تنظيفه دورًا حيويًا في الامتثال لمعايير السلامة الغذائية NSF/ISO.

ومع ذلك، فإن الفولاذ المقاوم للصدأ ليس الخيار الوحيد في بيئة المطبخ التجاري المعقدة اليوم. اعتمادًا على تدفق العمل، مناطق المهام، ومتطلبات النظافة، تقدم مواد أخرى لسطح العمل مزايا مميزة. فهم نقاط القوة والضعف لكل سطح يمكن أن يساعدك في اختيار التكوين المناسب، مما يحسن كفاءة المطبخ ومتانته على المدى الطويل.

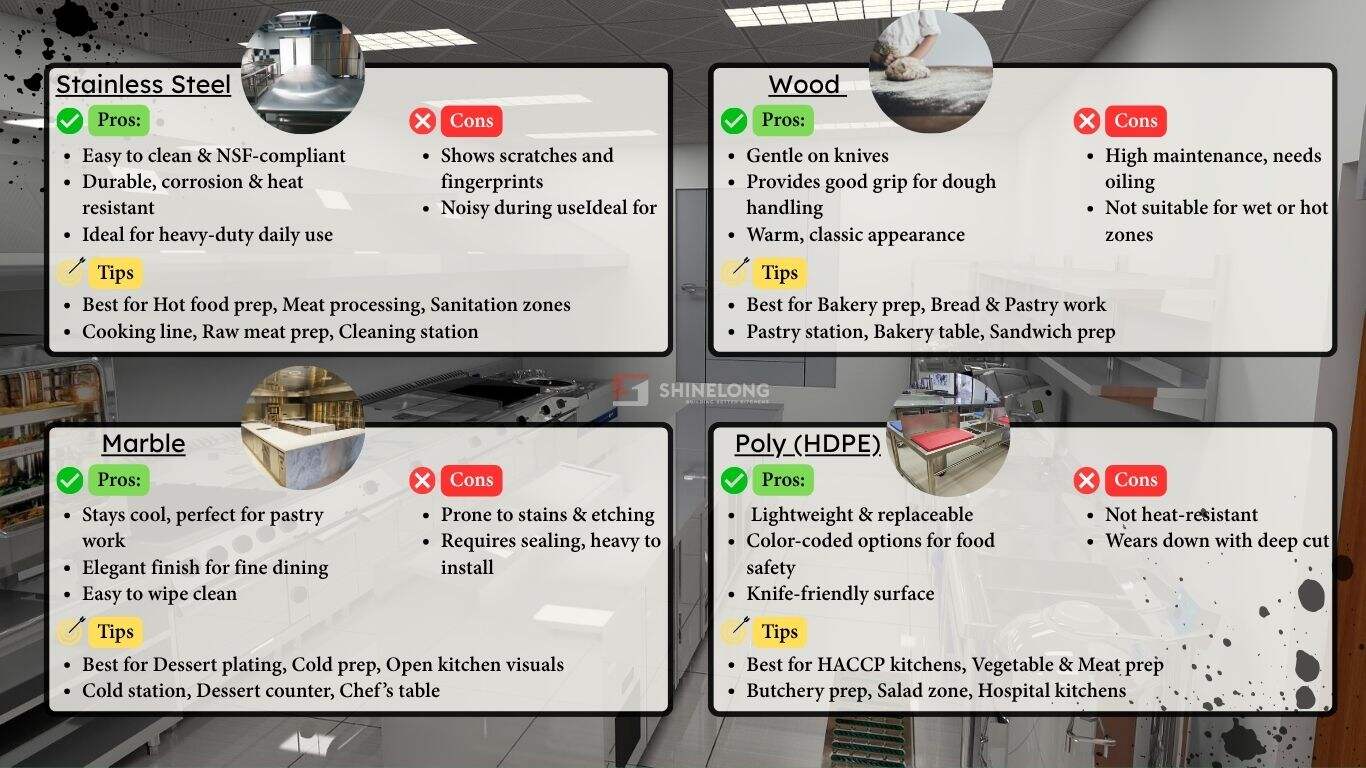

مواد الأسطح الشائعة المستخدمة في المطابخ التجارية

للاختيار الصحيح لمادة سطح طاولة العمل له تأثير مباشر على كل من الوظائف والأمان في المطبخ التجاري. يأتي كل نوع من مواد سطح العمل بمزاياه وقيوده الخاصة، مما يؤثر على كل شيء من النظافة إلى المتانة وكفاءة تدفق العمل.

في هذه المقالة، سنقدم مقارنة تفصيلية للمواد الأكثر استخدامًا في صناعة المطابخ التجارية، مما يساعدك على اتخاذ قرار مستنير بناءً على احتياجات تشغيل مطبخك.

سطح من الفولاذ المقاوم للصدأ

الستانلس ستيل من الدرجة 304 هو المادة المهيمنة لأسطح العمل في المطابخ التجارية بسبب مقاومته للتآكل وتحمله للحرارة. تجعل هذه الخصائص إياه مثاليًا لمناطق إعداد الطعام ذات التردد العالي. طاولات عمل من الفولاذ المقاوم للصدأ تُستخدم كنوع رئيسي من أسطح العمل في معالجة اللحوم، وإعداد المكونات، ومحطات إعداد الخط الساخن.

كما أنها ضرورية في مناطق غسل الأطباق وأرفف التخزين، حيث يُطلب الامتثال للمعايير الصحية. غالبًا ما يتم دمج طاولات العمل المصنوعة من الستانلس ستيل مع أدراج تحتية أو ظهور خلفية، مما يجعلها العمود الفقري التشغيلي للمطابخ الاحترافية.

قمة خشبية

تُعتبر أسطح الخشب، التي تُصنع عادةً من خشب القيقب الصلب أو البتش أو خشب الجوز، أساسية في المخابز وصناعة الحلويات أو مناطق تقطيع اللحوم. توفر سطحها الطبيعي شعورًا مرنًا، مما يجعلها مثالية للمهام التي تتطلب دقة يدوية، مثل عجن العجين أو تشكيل الخبز، والتي تحتاج إلى سطح متين قليلاً ومع ذلك مرن لمنع التصاق العجين دون تلف جودة نسيج الخشب الطبيعي. قدرتها على امتصاص الرطوبة الطفيفة وتقديم احتكاك متسق يجعلها مثالية لمعالجة المعجنات والخبز الحساس. يتم استخدام هذه الأسطح غالبًا في مناطق الإعداد حيث يتم التركيز على رعاية السكين، حرفة الطعام، وأناقة التقديم.

القمة الرخامية

إذا كنت تتساءل أي مادة سطحية للمطبخ تناسب بيئة المطبخ الفاخر، فإن الرخام هو بالتأكيد الخيار الأفضل. كحجر طبيعي فاخر، يقدم خليطاً نادراً بين الجماليات والوظيفية، مما يجعله الخيار الأول في مطابخ الحلويات، محطات الحلوى الراقية، وتصاميم المطابخ المفتوحة، حيث يهم الجاذبية البصرية بنفس قدر أهمية الأداء. سطحه البارد بشكل طبيعي مناسب بشكل خاص للتعامل مع المهام الحساسة للحرارة مثل تسوية الشوكولاتة، العجين المغلف، والأعمال الدقيقة للحلويات. ما يميز الرخام حقاً هو لمساته النهائية الأنيقة والرائعة. في قاعات الطعام الفاخرة والمخابز الصغيرة، أسطح رخامية تُستخدم غالباً لأسطح العدادات الأمامية أو محطات إعداد الطهاة، مما يضيف لمسة أبدية وفاخرة إلى المساحة الطهي.

بولي توپ

مصنوعة من البولي إيثيلين الكثيف (HDPE)، تقدم أغطية البولي حلًا خفيف الوزن ومتين لمناطق التحضير المكثفة مثل مناطق الجزارة، وأقسام معالجة الخضروات، والمطابخ المستشفية التي تتبع بروتوكولات سلامة الأغذية HACCP. في العمليات حيث يكون منع التلوث المتقاطع أمرًا حيويًا، تسهم الأسطح البوليمية الملونة في تبسيط ممارسات التعامل الآمن مع الطعام.

يتناسب هيكلها القابل للإزالة والسهل التنظيف مع متطلبات النظافة والقيود المكانية للمطابخ الوحدية، ومطابخ الأشباح، والتجهيزات التجارية القائمة على الحاويات، حيث تكون البروتوكولات الصارمة للتعقيم والإنتشار المرنة ضرورية.

كيف تختار المادة المناسبة لطاولة عملك

اختيار المادة المناسبة لسطح المنضدة ليس قرارًا واحدًا يناسب الجميع؛ فهو يتطلب فهمًا واضحًا لنوع المطبخ الخاص بك، وتدفق العمل اليومي، وأولويات الميزانية. على سبيل المثال، فإن مطبخ الغرب الساخن ذي الإنتاج العالي يتطلب عادةً سطحًا من الفولاذ المقاوم للصدأ بسبب أدائه الحراري والصحي، بينما قد تحتاج منطقة إعداد المأكولات الصينية إلى مزيج من الفولاذ المقاوم للصدأ ولوحات البولي إيثيلين الكثيف (HDPE) لمعالجة اللحوم النيئة والخضروات المقطعة مع تقليل مخاطر التلوث. في المقابل، فإن المخابز ومطابخ الحلويات تستفيد من أسطح خشبية أو رخامية، حيث توفر الملمس المثالي لمعالجة العجين وعمل الشوكولاتة.

في العديد من البيئات الاحترافية، يؤدي دمج المواد إلى أفضل النتائج. على سبيل المثال، يمكن الجمع بين محطة مركزية مصنوعة من الفولاذ المقاوم للصدأ لمهام التحضير والطهي الثقيلة مع كتلة خشبية جانبية لأعمال الخبز. هذا النهج يعزز توافق سير العمل ويدعم حركة منطقية من النظيف إلى القذر، وهو أمر أساسي لضمان النظافة ووضوح العمليات. يجب دائمًا مراعاة مدى توافق المادة مع تقسيم المطبخ الخاص بك - من الاستلام والتخزين إلى التحضير والطهي والتزيين النهائي - لضمان الكفاءة على المدى الطويل والامتثال للمعايير الصحية.

اتصل بنا للحصول على أثاث مطابخ تجارية مخصص

الكفاءة في تقديم الطعام تبدأ بأساس مطبخي صحيح. في SHINELONG , نتخصص في تصنيع موائد عمل من الفولاذ المقاوم للصدأ وحلول شاملة للمطابخ التجارية المخصصة لمساحتك وسير عملك ومعايير النظافة الخاصة بك. وبصفتنا واحدة من الرائدين مطعم مصنعي أثاث المطبخ في الصين، نقدم حلول متكاملة للمطابخ التجارية، ونعمل معك طوال المشروع كله، من الفكرة وحتى التركيب.

تعاون مع مصنع أثاث مطابخ صيني يحظى بثقة الفنادق والمقاهي الحاصلة على نجوم. اطلب اقتراح تخطيط 3D اليوم —تحسين خطوط الإعداد، وتقليل إرهاق الموظفين، وزيادة إنتاجية المطبخ.

ما بعد البيع:

ما بعد البيع:

EN

EN

AR

AR

HR

HR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

VI

VI

ET

ET

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

IS

IS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

UZ

UZ

KU

KU